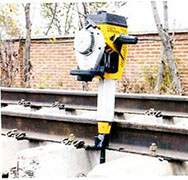

Hydraulic rail lifting machine |

||

|---|---|---|

|

|

|

The lifting machine is special equipment employed for lifting & lining operation of railway overhaul, medium maintenance, and track bed maintenance, suitable for the rail class 43kg/m to 75kg/m. |

||

Hydraulic switch-lifting machine

|

|

|

|---|---|---|

| The unit is suitable for lifting operation of turnouts, adaptable for rail class 43kg/m~ 75 kg/m. It adopts big supporting feet to ensure less sinking and big lifting range. The linkage working mode of landing parts and clamping parts may avoid mistaken operation. The complete system features simple operation, light weight, reliability and adaptable for various work. | ||

Rail lifting and lining machine

|

|

|

|---|---|---|

Rack jack Lifting capacity: 10T-15T |

Hydraulic rail lifting device Lifting capacity: 196KN |

Hydraulic rail lining device Lifting capacity:147KN |

Rail cutter

|

|

|

|---|---|---|

| The NQG-5 rail cutting machine is suitable to cut rails from Class 43kg/m to 75kg/m, complying with the railway standards of rail cutting surface. It has the structure of double swing handles. The cutting time is less than 2 mintues. The cutting disc features low cost, high utilization rate, quality cutting surface, and easy operation. The unit may move on both the ground and the track. | ||

Gasoline rail cutter

|

|

|

|---|---|---|

The mobile cutter is a key tool for railway maintenance, featuring high speed cutting, high accuracy, simple structure, light weight, easy to move, and convenient operation. |

||

Hydraulic rail stretching machine

|

|

|---|---|

| The unit can be used for repair of broken rails, stress relief of seamless rails, and adjusting the rail aperture of common rails, suitable for a variety of rails. By applying the unit, the rail workers could change the traditional means of repairing broken rails by welding at original location without inserting short rail, featuring time-saving and no change of rail temperature. | |

Hydraulic tamping machine

|

|

|---|---|

YD-22 hydraulic tamper is used for railway ballast repair for the rail line except turnouts during the timer interval of the train passing by. Three kinds of driving units, including gasoline engine, diesel engine, and electric-motor. |

|

Hydraulic tamping machine for turnout

|

|

|---|---|

| YCD-2 is specially designed for ballast of turnouts. The gasoline engine Honda GX270 is used as driving unit. It features swing-type moving frame, super impact force, and single-handle multiple exchange valve. | |

Diesel engine tamping machine

|

|

|

|---|---|---|

The tamping machine adopts single-cylinder, water-cooled, diesel engine to ensure super power and vibration force. It is the latest design features compact structure, high efficiency, safe & reliable. |

||

Portable gasoline tamping machine

|

|

|---|---|

Manual type gasoline-driven tamper is used not only for tamping the railway ballast, but also as impact breaker, featuring high efficiency, durability, and light weight. |

|

Portable grinding machine

|

|

|---|---|

| The grinding machine is used for rail top surface, side surface and fin edge, or for cutting vertical bolts, rusty removal, and grinding work. The unit features gasoline engine, punched frame, light and handy, easy operation, high cutting efficiency, portable, friendly maintenance, and suitable for different means of repair & service work | |

Railway grinding machine

|

|

|---|---|

| The NGM-4.8 grinding machine is used to grind rail welding seams of rail 43kg/m~ 75kg/m, uneven surface joint, fins of rail side, welding seam of rail top, and other positions. It features high efficiency, easy operation, perfect cutting & grinding result. | |

Gasoline switch grinding machine

|

|

|---|---|

| The NCM-4.0 grinding machine is used to grind the switch rail, the turnout center, rail top, side fins, fins of scissors crossover and stock rails. The two grinding units rectangular against each other may move and grind flexible to performance perfect operation at site. The grinding & cutting device can be adjusted to tilt 30 degree left or right, both in horizontal and vertical level, to ensure accurate cutting & polishing | |

Gasoline hole drilling machine

|

|

|

|---|---|---|

| The complete unit features 4-stroke gasoline engine, less vibration, stable drilling and automatic water cooling, and quick coupling. The special design of three-point clamp ensures quick locking and loose within 1 or 2 seconds. It is suitable to mount different rail cutter Ø9.80~ Ø36 | ||

Portable gasoline screwing machine

|

|

|---|---|

| NLB-800 is designed for fastening sleeper bolts, turnout bolts, fish plate bolts, spike, and any bolts & nuts | |

Rail joint adjusting machine

|

|

|---|---|

| The machine is used for rail joints at lower-level, or any other part of the rail, to adjust straightness and flatness. Suitable for any type of rails. It is a kind of effective tooling to fix the problems of rail joints | |

Railway crimp welding machine

|

|

|---|---|

| The mobile air welder is used for welding the rails. Its working means is pressure-maintaining push convex type. The pressure connection unit is positioned under the rail to ensure horizontal straightness of two rails. Being compared with similar products, it features unique concept, reasonable design, and easy operation. | |

Hydraulic rail gap adjusting device

|

|

|---|---|

| The machine is a small tool to adjust rail gap during railway maintenance, suitable for any rails range 43kg~75kg/m, featuring small size, light weight, super thrust, convenient operation and easy handling | |

鲁ICP备08105062号